BOPP Tape Jumbo Roll, 1600mm×1000m, 45μm/50μm Thickness, Acrylic Adhesive, Transparent/Colored, Suitable for Carton Sealing, Packaging & Industrial Bonding

Place of Origin: Hebei, China

Brand Name: Customizable (OEM/ODM Accepted)

Model Number: Blackspider-1

Certifications: SGS, ISO9001, RoHS

- Overview

- Business Terms

- Product Description

- Application Scenarios

- Product Specifications

- Competitive Advantages

- Recommended Products

1. Alternative Names: BOPP Adhesive Tape Master Roll, BOPP Jumbo Roll, Industrial Packaging Tape Master Roll, Acrylic BOPP Master Roll

2. Main Applications: Raw material for slitting into standard BOPP tapes (18mm/24mm/48mm width); Widely used in industrial packaging, carton sealing, product bundling, logistics transportation and surface protection in manufacturing industry

3. Core Specifications & Parameters: Model BMR-1600-45, Material BOPP Film + Acrylic Adhesive, Width 1600mm (Customizable), Length 1000m/Roll, Thickness 35-60μm (Optional), Adhesion ≥1.2N/25mm, Tensile Strength ≥25MPa, Elongation at Break ≥180%

Minimum Order Quantity (MOQ): 5 Rolls (Negotiable for Bulk Orders)

Price: 1.2-1.8 USD/Square Meter (Tiered Pricing Based on Thickness, Quantity & Customization Requirements)

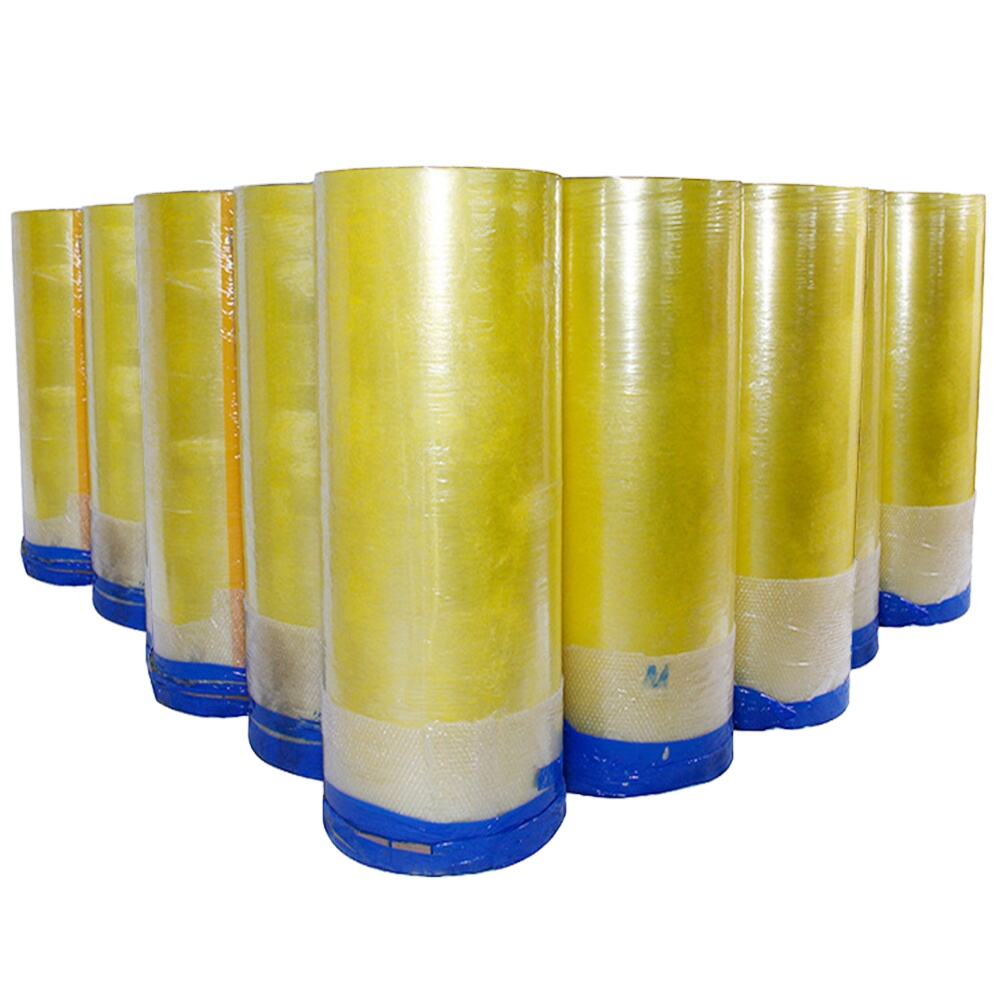

Packaging Details: Each master roll is wrapped with moisture-proof PE film and then loaded onto wooden pallets; Pallet Dimension: 165cm×120cm×110cm; Gross Weight: 250kg/Pallet

Delivery Time: In-stock standard rolls shipped within 3-5 working days; Customized orders take 7-12 working days

Payment Terms: Telegraphic Transfer (T/T, 30% advance payment, 70% balance paid against B/L copy), Letter of Credit (L/C) at sight, Western Union (Applicable for Sample Orders)

Supply Capacity: 10,000 Rolls/Month

BOPP Tape Master Roll is a high-quality base material for packaging tape production, featuring biaxially oriented polypropylene (BOPP) film as the substrate and high-performance acrylic adhesive as the bonding layer. As a core product in the packaging material industry, it boasts excellent mechanical properties and stable bonding performance, capable of meeting various slitting processing and subsequent packaging application requirements.

The product adopts advanced biaxial stretching technology for BOPP film processing, endowing the master roll with outstanding tensile strength and toughness. With a tensile strength of no less than 25MPa and an elongation at break of over 180%, it can withstand the tension during slitting, avoiding breakage or deformation. The acrylic adhesive layer is uniformly coated via precision coating technology, featuring strong initial adhesion and holding power (adhesion ≥1.2N/25mm). It also possesses excellent temperature resistance (adapting to -10℃~60℃) and weather resistance, without degumming or peeling in harsh environments such as high temperature, humidity and cold.

BOPP Tape Master Roll is available in multiple colors including transparent, white, yellow and blue, meeting customers' diverse needs for product appearance and functional differentiation. The surface of the master roll is flat and smooth, free of bubbles, wrinkles and impurities, ensuring the quality of slit small rolls. Non-toxic and odorless, the product complies with RoHS environmental standards, making it suitable for packaging scenarios with strict environmental requirements such as food, medicine and electronics. Whether for small packaging tape processing factories or large logistics and packaging enterprises, our BOPP Tape Master Roll can provide reliable quality assurance for your production and operation.

1. Tape Slitting Industry: Slit into standard-width BOPP packaging tapes (e.g., 18mm, 24mm, 36mm, 48mm) for daily and industrial use

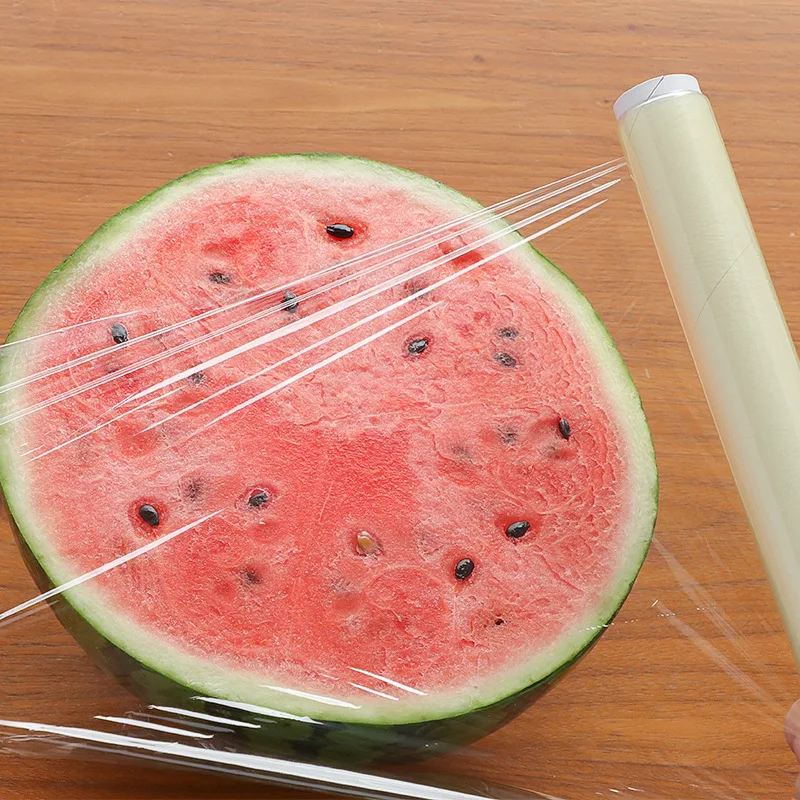

2. Industrial Packaging: Directly used for large carton sealing, heavy goods bundling and packaging material fixing in factories, warehouses and logistics centers

3. Logistics Transportation: Used for reinforcing carton seals during long-distance transportation to prevent carton opening caused by vibration and extrusion

4. Manufacturing Surface Protection: Temporarily protect product surfaces (e.g., furniture, home appliances, plastic products) during production and processing to avoid scratches and contamination

5. Printing & Labeling: Serves as the base material for printed BOPP tapes, used for product identification, brand promotion and anti-counterfeiting packaging

6. Other Fields: Used for agricultural product (e.g., fruits, vegetables) bundling, building material sealing and temporary fixing at construction sites

|

Specifications & Parameters |

Specific Values/Information |

|

Product Model |

Blackspider-1 (Customizable by Width & Thickness) |

|

Product Material |

BOPP Film (Biaxially Oriented Polypropylene) + Acrylic Pressure-Sensitive Adhesive |

|

Product Width |

1600mm (Common Widths: 1200mm, 1400mm, 1600mm; Customizable) |

|

Product Length |

1000m/Roll (Optional: 800m, 1200m; Adjustable per Customer Requirements) |

|

Product Thickness |

35μm, 40μm, 45μm, 50μm, 60μm (Customizable Thickness Range: 30-80μm) |

|

Adhesion |

≥1.2N/25mm (Test Standard: GB/T 4852-2002) |

|

Tensile Strength |

≥25MPa |

|

Elongation at Break |

≥180% |

|

Color |

Transparent, White, Yellow, Blue, Green, Customizable Color |

|

Temperature Resistance Range |

-10℃~60℃ |

|

Certification Standards |

SGS, ISO9001, RoHS |

|

Core Diameter |

76mm (Standard), 152mm (Optional) |

1. High-Quality Raw Materials: Adopts imported BOPP film and high-purity acrylic monomer for adhesive production, ensuring stable product performance and long service life

2. Advanced Production Equipment: Equipped with German precision coating machines and fully automatic slitting machines, achieving high-precision coating, uniform thickness, and no defects such as bubbles or uneven adhesion

3. Customization Capability: Supports customization of width, length, thickness, color and adhesive type (acrylic, hot-melt), meeting personalized needs of different customers

4. Cost-Effectiveness: Large-scale production reduces unit cost, providing customers with high-quality products at competitive prices; High utilization rate of master rolls reduces losses during slitting

5. Strict Quality Control: Implements full-process quality inspection from raw material warehousing to finished product delivery, equipped with professional testing equipment to ensure each master roll meets standards

6. Comprehensive Logistics Services: Cooperates with well-known logistics companies to provide sea, air and land transportation services; Moisture-proof and shock-proof packaging ensures goods are intact during transportation

7. Professional After-Sales Team: Provides 24/7 online consulting services; In case of quality issues, timely provides solutions such as return, replacement and compensation