If you’re sending a package in the mail, you’d probably use tape to help keep it closed. But did you realise that you can make your packages look cool using patterned tape? Today, we’re going to know the fun world of custom printed tape and why your packages will benefit from using it.

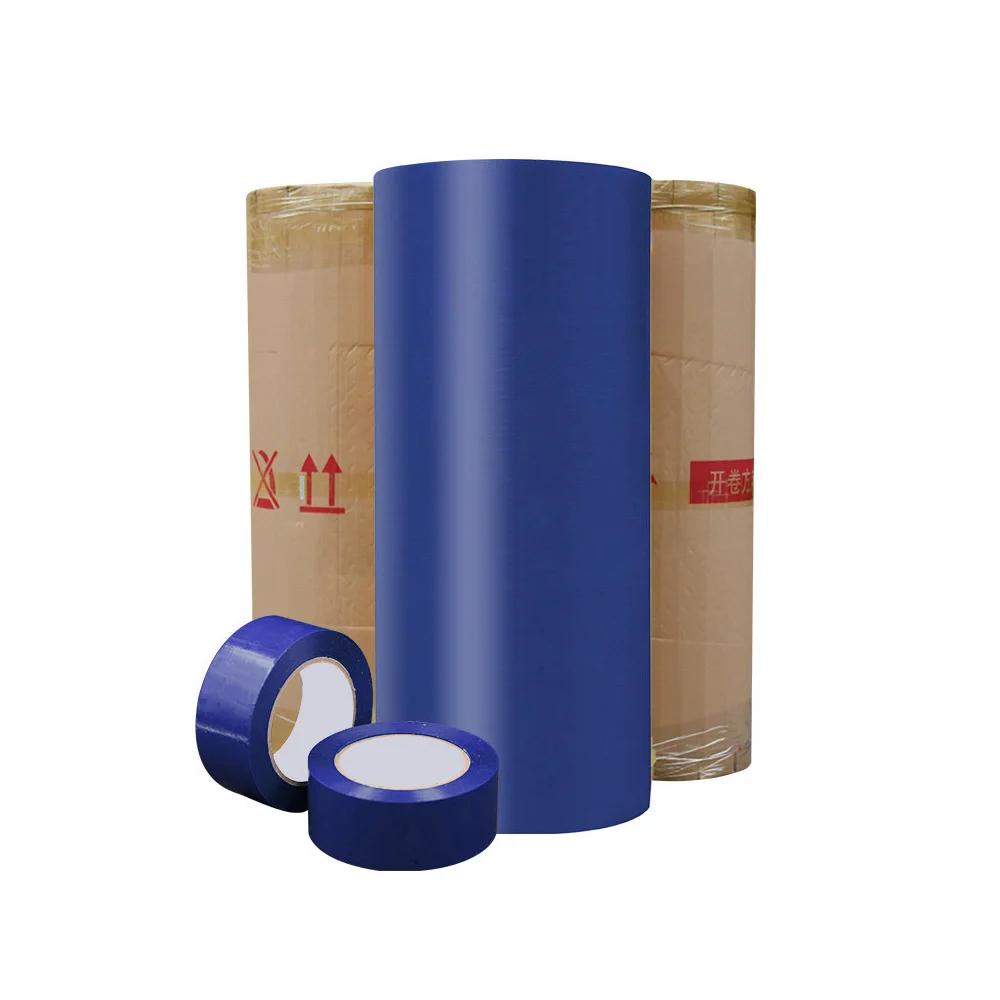

Custom tape is the equivalent of a blank piece of paper you can decorate yourself. You can add your company logo, a fun pattern, or a special message to make your packaging one of a kind. There are so many things you can do with custom Packaging Tapes.

Printed tape makes your packages look more exciting. Whether you're sending a gift to a friend or sending products to customers, branded Specialty Tapes can make your packages stand out. Your baguettes will be the baguettes everyone sees.

Get creative with printed custom tape. You may choose from various designs and colors to make your packs unique. And whether you desire a bold, colorful pattern or a clean, nice design, there’s some printed custom tape to complement your style.

Forget having boring brown tape or duct tape on your packages when you can have personalized printed tape that includes your company logo. Your Customers will see your printed tape and Remember your brand. That helps them trust and love your products even more.

Printed tape says you are a detail-oriented person. It makes your packages look professional and sends the message to your customers that you take your work seriously. Printed tape is one easy way to make the introduction of your package to your customers exciting.

Established in 2003, we offer end-to-end control—from raw material procurement and adhesive formula R&D to production, slitting, and packaging—ensuring consistent quality, shorter lead times, and direct customer collaboration.

We incorporate recyclable materials and sustainable production practices while maintaining cost‑effective pricing. Our products are trusted by domestic leaders and exported to the Middle East, Southeast Asia, Europe, America, and South Africa, building long‑term global partnerships.

All products meet ISO, SGS, and ROHS certifications, backed by a 12‑stage quality assurance system. We also provide rapid prototyping (72‑hour samples), factory audits, design drafts, and full service tracking from order to delivery.

With a monthly output capacity of 5,000 tons and a modular production system, we reduce custom order lead times from the industry average of 20 days to just 7–15 days, supported by 30+ machinery systems serving over 400 client facilities.